This is a project for a Saudi Arabia based client who has asked us to customize a croissant automatic packaging line to meet their automated packaging needs. The main functions of this packaging system are as follows:1. Remove croissants from the ove...

This is a project for a Saudi Arabia based client who has asked us to customize a croissant automatic packaging line to meet their automated packaging needs. The main functions of this packaging system are as follows:

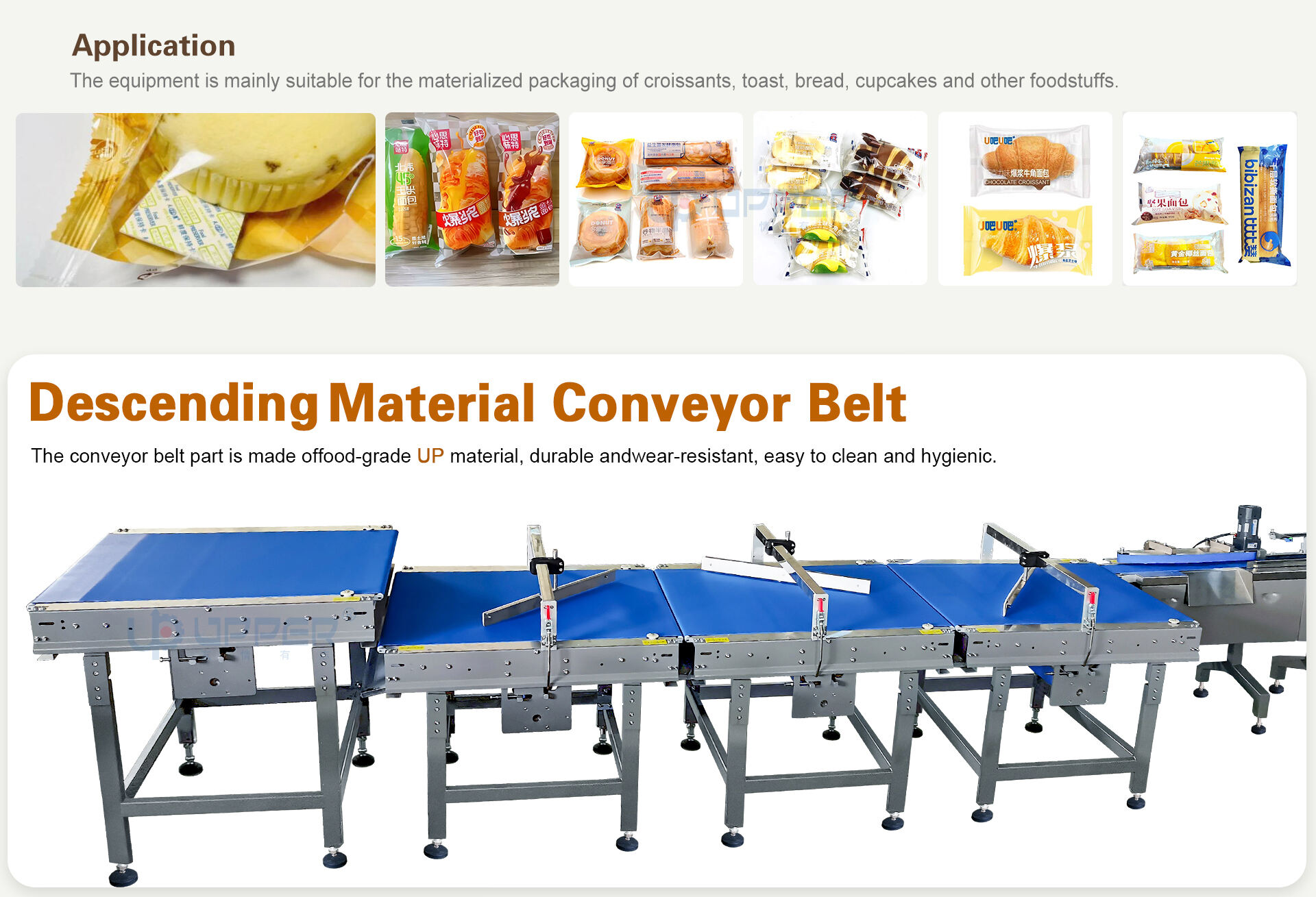

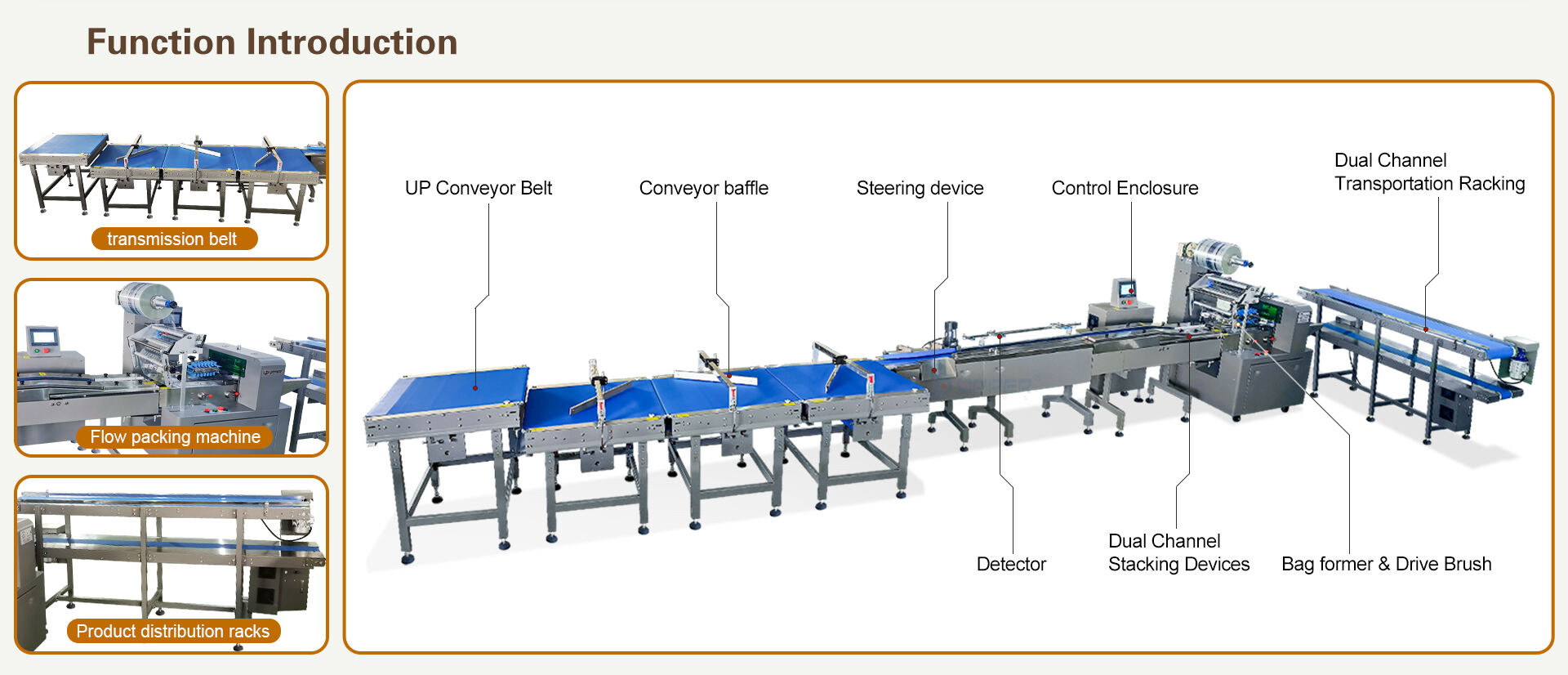

1. Remove croissants from the ovenware and place them on a conveyor unit.

2. the conveyor unit has the functions of material sorting, picking and diverting.

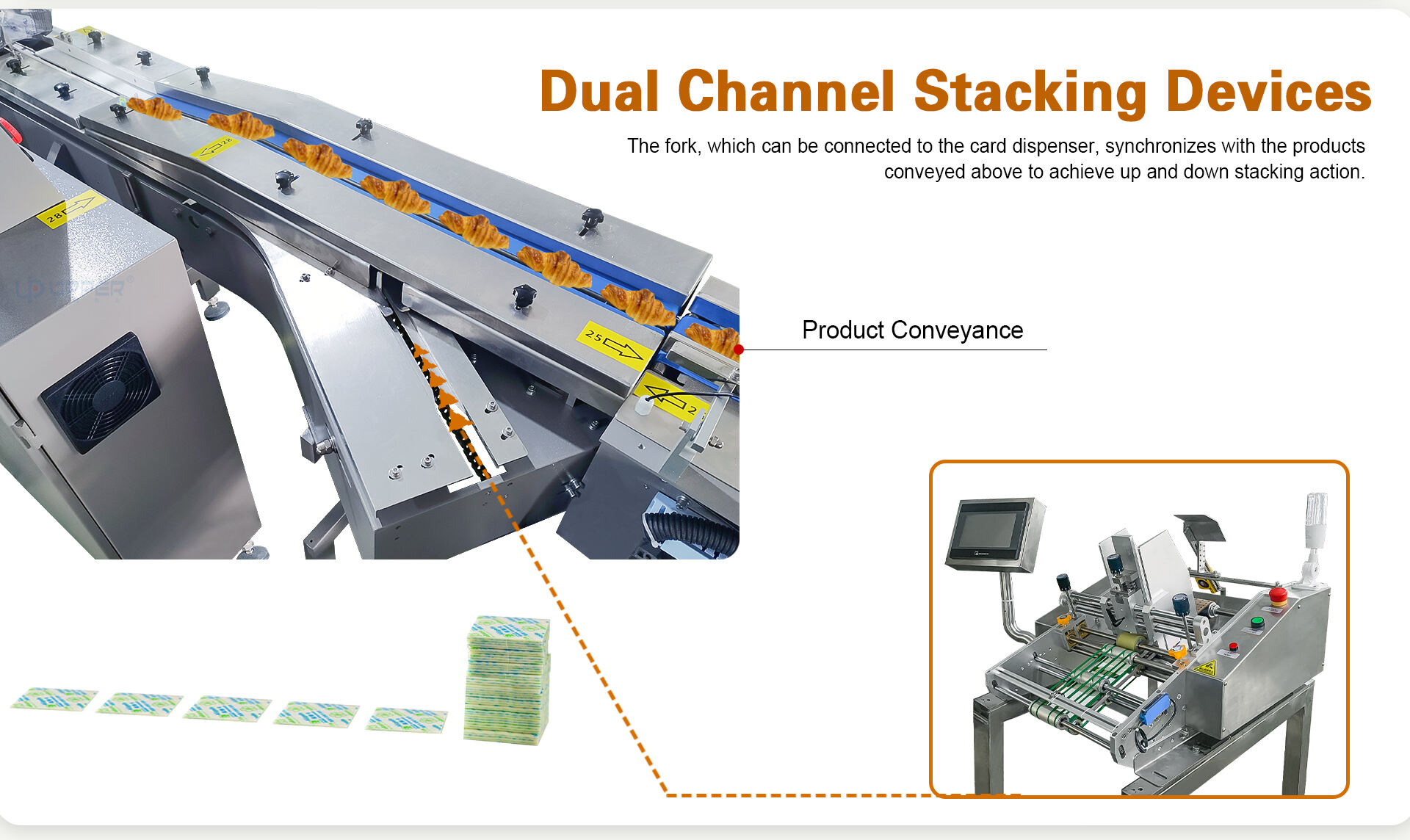

3. then the material is rationalized and conveyed through the three-stage detection of the rejecting action.

4. On the way, it can be linked with the dispenser to dispense the preservative for synchronized stacking and conveying.

5. Performs automatic packaging with bagging/sealing/cutting action.

6. the back end can be linked with the dual channel conveyor rack (when the finished product reaches the exit, if there is an abnormality or manual selection is required, the material can be manually placed on the upper level and conveyed to the back end)