A case packing system is a machine that is made to automate the process of putting products into shipping cases or cartons. They are used in nearly every manufacturing and distribution industry because they create uniformity while making packaging easy for transportation and storage. Case packaging systems are made up of many different machines and conveyors that work together to handle, pack, and seal products into cases.

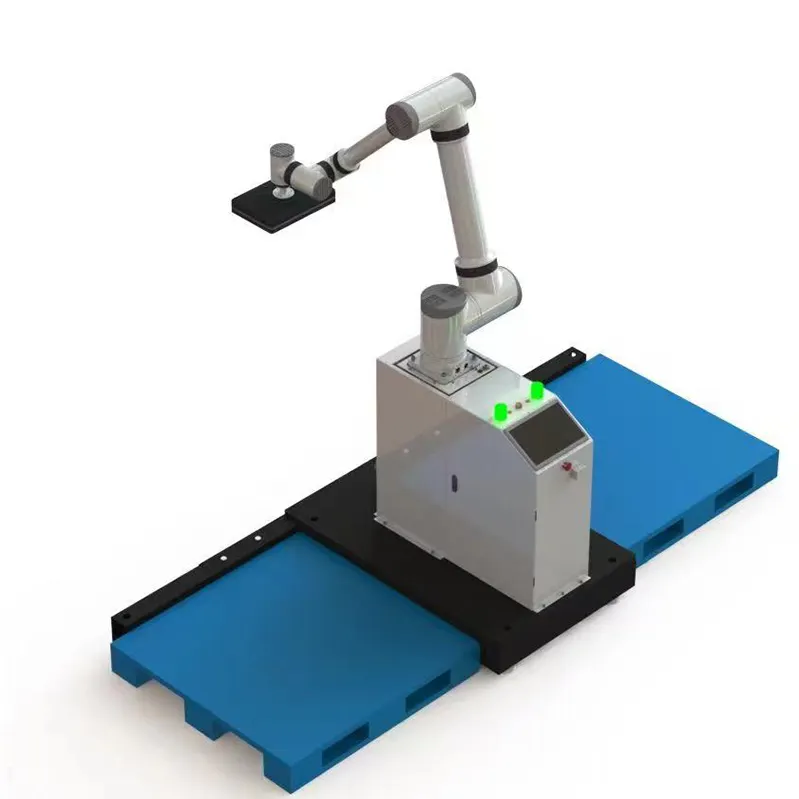

The first part of a case packing system is preparing the shipping case. This can include forming the case from flat cardboard sheets, applying adhesive tape or glue to seal the bottom, etc., just as long as it’s ready for products to be put inside of it. After this has been completed; next comes the product section where items are placed and oriented correctly within a box before being shipped out . Depending on what type of system you have there might be robotic arms involved with conveyor belts but either way they should be able to handle everything safely while being efficient at what they do.

Once everything has been packed into its respective places within each individual package then closed off by sealing all flaps shut tightly enough so nothing falls out during transit ; finally moving onto labeling or palletizing stages depending upon where exactly these containers need to go next . A wide range sizes can be handled with such variety in products being packaged which makes versatility key when designing these units for use across multiple industries.

Foshan Upper Machinery Equipment Co., Ltd. was founded in2011. It is an innovative automated packaging equipment manufacturer integrating R&D, design, manufacturing, sales and after-sales. Since its establishment more than ten years ago, the company has attracted a group of more than 80 professionals who are persistently pursuing the mechanical industry. The number of talents who have grown up with the company has reached 12, and they have designed and manufactured automatic packaging equipment with leading technology in China and oversea.

The company specializes in manufacturing: automatic product flow packaging line, pillow packaging machine, food packaging machine, daily chemical products packaging machine, hardware accessories packaging machine, pouch dispenser, secondary packaging machine, automatic carton packing filling machine, bag sorting machine, customized counting collection machine, customized processing line packaging equipment.

Our UPPER automatic packaging lines are designed to maximize efficiency, reducing packaging times by up to 50% compared to traditional methods. This rapid throughput ensures your products get to market faster, giving you a competitive edge.

With UPPER, precision is paramount. Our automatic packaging lines ensure each product is wrapped and sealed with exacting standards, minimizing waste and guaranteeing a professional presentation that enhances your brand's reputation.

Invest in UPPER for long-term savings. Our automatic packaging lines significantly reduce labor costs and material waste, offering a cost-effective solution that optimizes your packaging budget without compromising on quality.

UPPER offers a variety of case packaging systems designed for different industries and applications. These may include automatic, semi-automatic, and custom-designed systems to meet specific packaging needs.

Yes, UPPER case packaging systems are versatile and can accommodate a wide range of product sizes and shapes. They often feature adjustable mechanisms to ensure proper packaging for different items.

Regular maintenance is essential to keep case packaging systems running smoothly. This typically involves routine inspections, cleaning, and replacing worn parts as needed.