The objective of a sorting machine is to arrange things according to specific criteria in an automated manner. These devices find application in various sectors such as manufacturing, logistics, recycling or even agriculture among others with the aim of streamlining operations and increasing efficiency. They use sensors, cameras and computer algorithms that are based on advanced technologies to recognize objects and separate them by features like size, shape, weight, colour or material composition.

A popular type of sorting machine is the conveyor belt sorter where items are moved along a belt while their properties are detected by sensors. Depending on the information it gathers, this system directs every item into correct bin or chute. Another example includes optical sorters which scan items using cameras and lasers to make decisions about how they should be sorted out. Such machines come in handy especially at recycling plants where different kinds of materials can be separated quickly and accurately.

There are many benefits associated with using sorting machines instead of doing it manually. They have ability to handle large quantities within short periods thereby saving on labour cost besides reducing chances for errors during operation process due to fatigue or lack concentration among workers involved in doing repetitive tasks . These devices also enhance safety since they eliminate need for human beings handle potentially dangerous substances which may lead into injuries if mishandled either intentionally or inadvertently during collection process from one point another within any given facility . With advancement in technology, more sophisticated sorting machines have been developed which offer higher precision levels together with wider variety functions applicable across different types tasks areas involving sorting activities.

Foshan Upper Machinery Equipment Co., Ltd. was founded in2011. It is an innovative automated packaging equipment manufacturer integrating R&D, design, manufacturing, sales and after-sales. Since its establishment more than ten years ago, the company has attracted a group of more than 80 professionals who are persistently pursuing the mechanical industry. The number of talents who have grown up with the company has reached 12, and they have designed and manufactured automatic packaging equipment with leading technology in China and oversea.

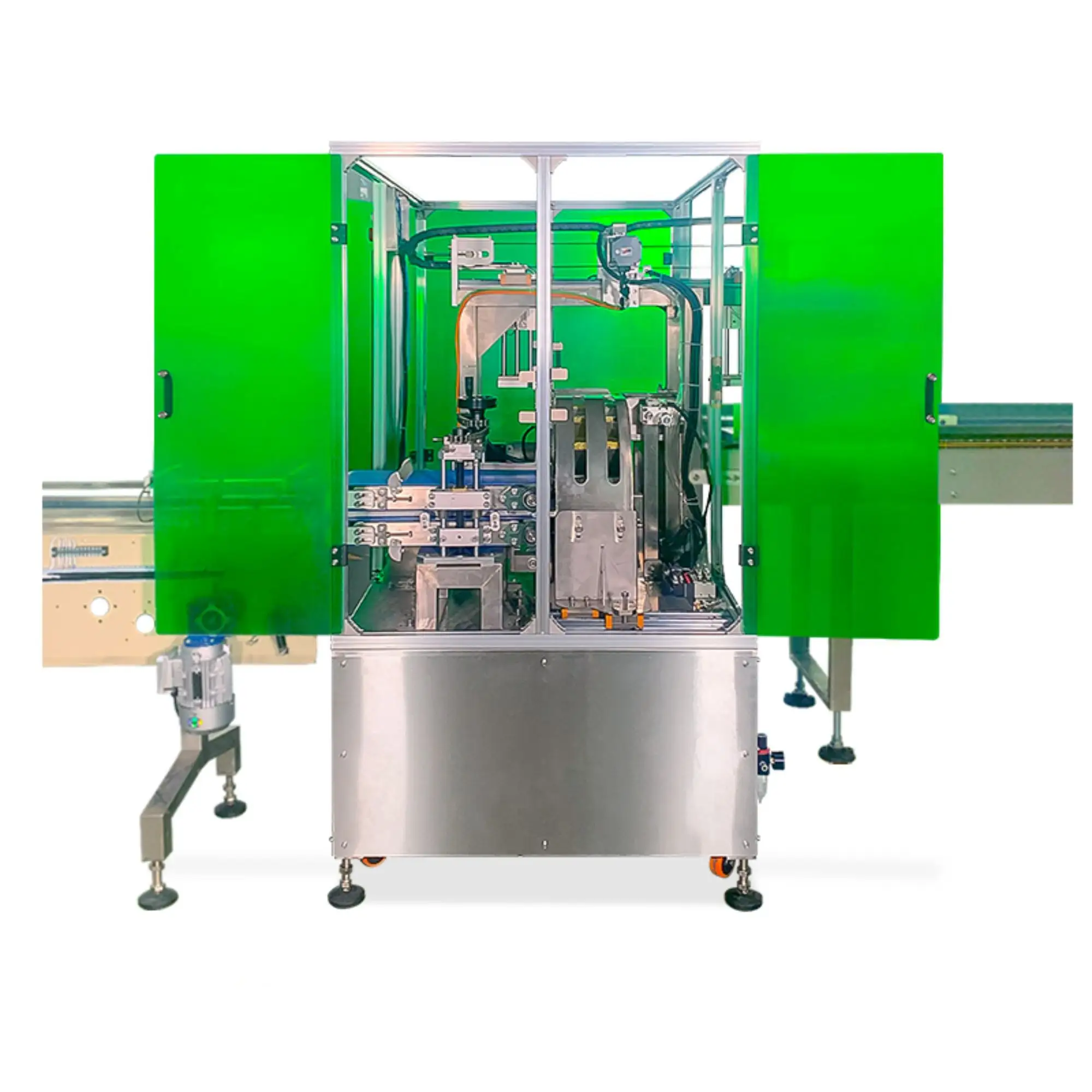

The company specializes in manufacturing: automatic product flow packaging line, pillow packaging machine, food packaging machine, daily chemical products packaging machine, hardware accessories packaging machine, pouch dispenser, secondary packaging machine, automatic carton packing filling machine, bag sorting machine, customized counting collection machine, customized processing line packaging equipment.

Our UPPER automatic packaging lines are designed to maximize efficiency, reducing packaging times by up to 50% compared to traditional methods. This rapid throughput ensures your products get to market faster, giving you a competitive edge.

With UPPER, precision is paramount. Our automatic packaging lines ensure each product is wrapped and sealed with exacting standards, minimizing waste and guaranteeing a professional presentation that enhances your brand's reputation.

Invest in UPPER for long-term savings. Our automatic packaging lines significantly reduce labor costs and material waste, offering a cost-effective solution that optimizes your packaging budget without compromising on quality.

UPPER provides a variety of sorting machines designed for different applications, such as food processing, recycling, and logistics. They may include belt sorters, chute sorters, and robotic sorters, among others.

UPPER sorting machines are engineered for high accuracy, ensuring that items are sorted efficiently and with minimal error rates. The exact accuracy depends on the model and application but typically meets industry standards.

Yes, UPPER offers sorting solutions that are capable of handling fragile items with care. These machines often feature gentle handling mechanisms to prevent damage during the sorting process.