Elegance Meets Efficiency: Case Packaging System Solutions for Snacks

The Need for Efficient Snack Packaging

In the ever-growing competitive snack sector, brands need to be fully aware of how vital these products are and how best to pack them. There is a growing necessity and demand for packaging solutions that are both creative and effective, especially considering the growing shift to consumer-centric behaviors. This is where case packaging systems come in. They allow everything to be neatly packaged without compromising on form.

What Makes a Case Packaging System Efficient?

Operating Speed: With proper automation and mechanisms, operating a case packaging system can be very quick. Packaging systems are fully designed to operate at a specific speed and efficiently do so during peak production times. They can adapt to operating at various speeds which in turn raises their efficiency.

Versatility Across Product Lines:Imagine using a case packaging system that can work for a vast number of items from biscuits to candies easily. The lack of variability in format leads to reduced material requirement and cost. This level of efficiency means that all forms of production can be completed under one machine and brand.

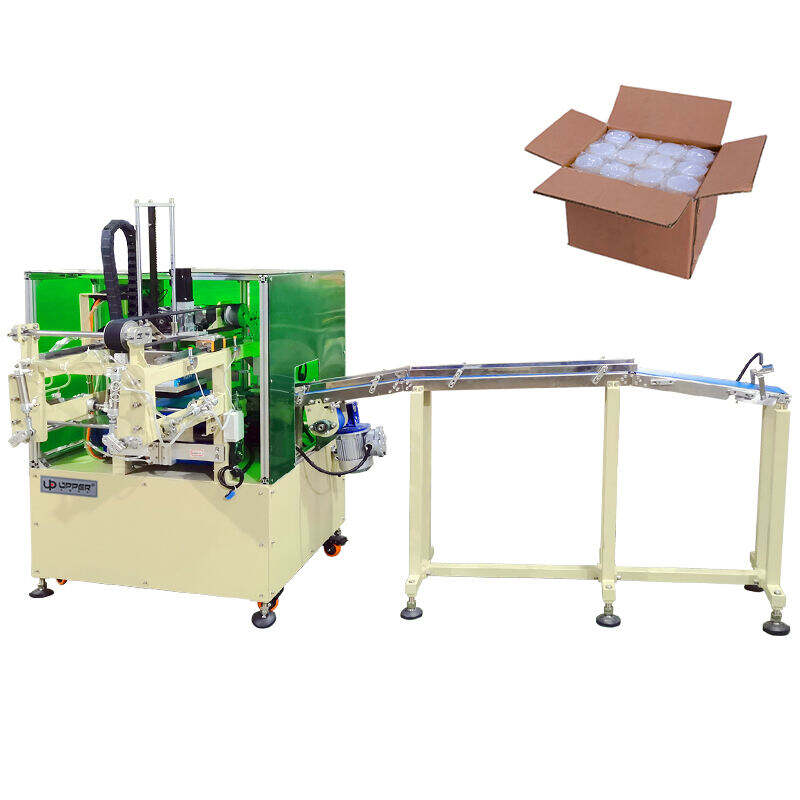

How Upper's Case Packing Machines Are Made To Be Efficient

Snack case packaging system is a key part of our operation at Upper. Our Philosophy When engineering case packing systems is to combine performance optimbolity and beauty together.

Automation At Its Best: Our case packaging systems boast the best in automated and robotic packers to guarantee the speed and accuracy needed for each task. The integration of servo motors with control panels guarantees the required movements for maximum output with little to no wastage.

Brand Specific Needs: We believe that all snack manufacturers have different requirements and for that reason, we have the option of fully adjustable case packaging systems to cater to all needs. That can be changing the box dimensions to including a nitrogen purging system for longer shelf life.

Guided approach: The basic requirement of a case packing machine is ease of use; this is what makes our case packaging systems unique. The user’s ability to activate control interfaces via touchscreen and easily changing settings with visual instructions provides the needed flexibility. This also enables better training results and cost reduction.

EN

EN

AR

AR

FR

FR

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

KO

KO

JA

JA

VI

VI

NL

NL

IT

IT

DE

DE